|

|

Shrinkage and Distortion Calculation | _Strengths

_Material

_Component Design

_Processing Conditions

_Mold Technology

_Gate Design and Location

_End of page

In the production of plastic components, melt is injected into the mold cavity. After completion of the injection phase and the hold period, the molding is cooled down to the temperature for removal from the mold during the cooling period. Due to physical factors, the plastic component undergoes a dimensional change during the cooling process that is specific to the material used. This dimensional change is called shrinkage.

In the case of non-reinforced amorphous plastics, uniform shrinkage (isotropic behavior) takes place because of the morphologocial structure. Semi-crystalline plastics, with which varying shrinkage occurs (anisotropic behavior) depending on the crystallinity and its aligmnent, behave differently. These differences in shrinkage may lead to stress in the molding that can cause distortion of the component after removal from the mold. This dimensional change in the molding must be taken into account in the mold design so as to obtain a dimensionally accurate component after cooling.

| | Shrinkage | - Increase in confidence level

Basic Principles of Shrinkage When thermoplastics are processed using the injction molding method, the moldling dimensions change during the cooling phase. These dimensional changes are referred to as "shrinkage." Shrinkage is based on the compressibility and thermal expansion of the plastics. When thermoplastics undergo shrinkage, the volume changes. To retain the desired dimensions of the plastic part, the mold cavity is enlarged by the amount of shrinkage of the plastic. Therefore, the tool and die maker must predict shrinkage-related dimensional differences between the mold cavity and the molding. This is not easy in many cases since shrinkage is determined by a large number of influencing factors. If the designer incorrectly estimates the shrinkage, distortion of the components results. In addition to process control variables (temperature, pressure) and the material properties (p-, v-, d-behavior, fillers, amorphous, semi-crystalline), the rigidity and the wall thickness of the molding influence the shrinkage. Although shrinkage is based on thermal expansion, the effective reduction in size after removal from the mold is less than would be expected with purely thermal expansion. Additional mechanisms play a role in shrinkage, leading to a reduction in the thermal contraction in relation to purely thermal expansion. The most important mechanisms are:

- Internal stress, influenced by:

- temperature profile during cooling

- cavity surface temperature in both halves of the mold

- Crystallization in semi-crystalline thermoplastics, influenced by:

- cavity surface temperature

- cooling curve (effectiveness of the cooling system)

- Mechanical obstruction of shrinkage, influenced by:

Furthermore, the thermal contraction is influenced by the thermodynamic process during injection molding, particularly by:

- the pressure curve during cooling

- the hold pressure effectiveness and the shear load on the melt due to the gate design and location

- the melt tmeperature and other processing conditions

Since shrinkage is a time-related variable, the time at which the shrinkage is measured after removal from the mold should be indicated to provide for a precise definition. A distinction is made between:

- ejection shrinkage, Se, which is measured immediately after the part is removed from the mold

- processing shrinkage, Sver, which is calculated after approx. 16 hours of storage in a normal climate and represents the difference between the dimensions of the cold mold and the molding

- after-shrinkage, Sn, which may cause a further dimensional change after long storage, especially under the influence of temperature.

The results in total shrinkage, which consists of the processing shrinkage and after-shrinkage. If one examines the overall framework of shrinkage, four main variables can be described:

- material

- processing conditions

- component design

- mold technology

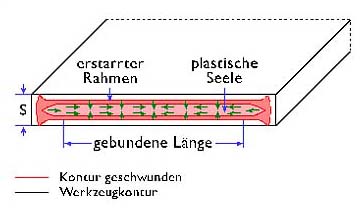

| | Shrinkage conditions at the component | The varying shrinkage behavior of amorphous and semi-crystalline plastics can be illustrated very well in a p-, v-, d-diagram. In contrast to amorphous plastics, crystallization occurs in semi-crystalline plastics in the course of cooling when the temperatures of the piece falls below the crystallization temperature. A nearly defect-free order is creatd in this process, resulting in considerable shrinkage. The crystallization behavior depends on temerpature and time. In the case of slow cooling, a high degree of crystallization ensues, i.e., the shrinkage rises. If the temperature drop is rapid, a lower degreee of crystallization results and thus less processing shrinkage. However, increased after-crystallization may occur under a temperature load, leading to undesired after-shrinkage. Fillers influence the shrinkage behavior due to their low expansion capacity. While round fillers generally reduce shrinkage, glass fibers generate shrinkage differences depending on the orientation. Shrinkage is reduced to a greater extent longitudinally to the orientation than cross-wise to the glass fiber layers. This behavior must be taken into account inthe design of the gating system since the shrinkage differences that arise may lead to distortion in the event of an unfavorable glass fiber position in the mold.

In addition to surface quality requirements, plastic components must also meet mechanical requirements. To achieve functionality, ribs and other structural measures are necessary. To avoid surface marks, these ribs are designed with a small wall thickness. However, wall thickness differences may lead to varying shrinkage behavior that is weaker or stronger depending on the plastic used. In the case of semi-crystalline materials, a large wall thickness results in slower cooling, which then leads to greater shrinkage. This behavior is more pronounced in semi-crystalline materials than in amorphous thermoplastics. The resulting shrinkage differences in the molding lead to internal stresses in the molding, which are either absorbed through the inherent rigidity of the structure or reduced through special processing conditions.

During processing the hold period and amount of hold pressure have the greatest influence on the shrinkage behavior of the component. During the hold period, melt continues to be inserted into the molding via the plastic core, thus partially compensating for the shrinkage behavior. If the gating system and the molding are designed optimally, a reduction in shrinkage of up to 0.5% can be achieved with semi-crystalline thermoplastics. In the case of amorphous materials, maximum values of only 0.2% are attained because of the lower shrinkage potential. The mold wall temperature not only determines whether the hold pressure effect is better or poorer, but also the cooling speed. At a high wall temperature the molding cools down more slowly. With semi-crystalline materials this leads to more pronouned crystallization and thus to increased processing shrinkage.

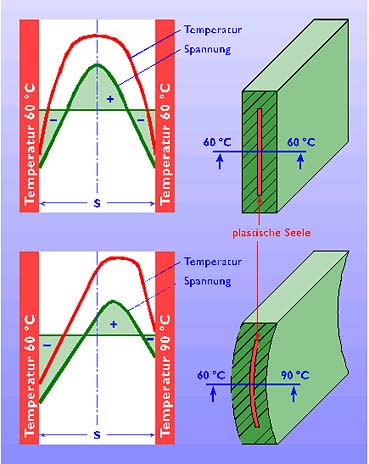

Different temperatures in different mold areas leads to varying shrinkage and thus varying molding properties. In the case of an uneven mold temperature between the inside and outside of the molding, the plastic on the warmer side shrinks more than on the side with the lower temperature. During this uneven cooling process there is a shift in the temperature profile in the solidifying melt, resulting in varying shrinkage potential and varying cooling stress in the molding.

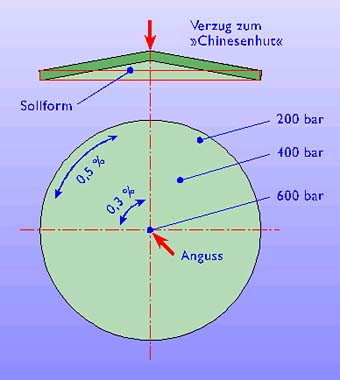

| | Shrinkage differences due to varying mold temperature | The gate position is often very critical with respect to shrinkage. To guarantee trouble-free separation of the gating system from the molding, a very small gate is frequently selected. The resulting cross-section then freezes quickly as soon as no more melt is pressed through the gate. Since one works with only a very small flow rate during the hold period, the shear heat produced in this process is not sufficient to keep the gate clear. A prematurely frozen gate reduces the effectiveness of the hold period so that surface faults and shrinkage differences in the case of varying wall thicknesses can be expected. In addition to the gate design, the gate location also plays a major role in the shrinkage behavior. Consequently, the flowability of the material used should not be completely exploited to the maximum when designing the gating system. Excessively long flow paths influence the effectiveness of the hold pressure and thus the shrinkage behavior as well. Because of the pressure differences in the molding, less shrinkage occurs near the gate than in areas far from the gate.

| | Hold pressure impact close to and far from the gate | | | |

|

|

|

|

|